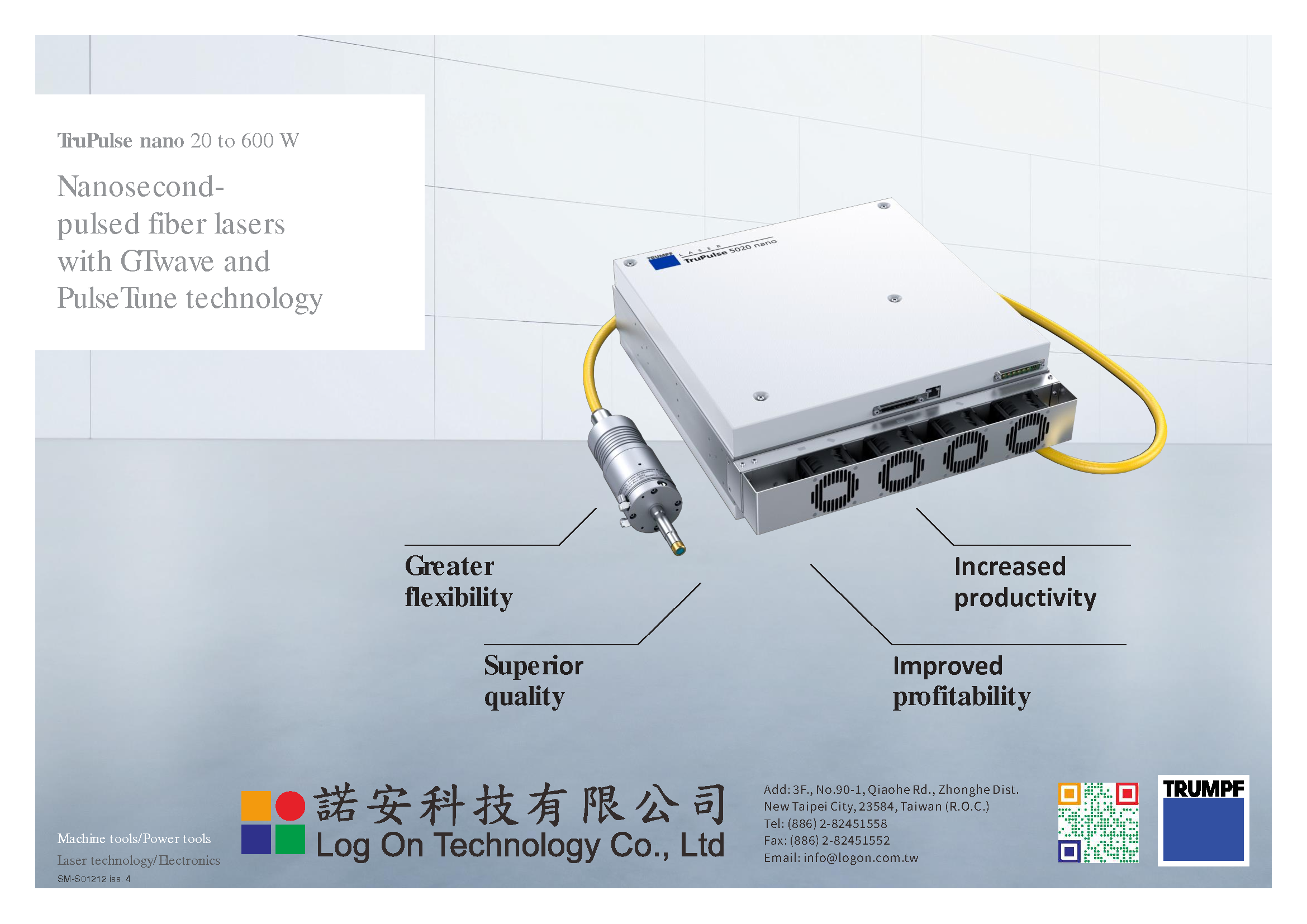

The Trumpf TruPulse nano, a pulsed fiber laser equipped with GTWave and PulseTune technologies, is one of the most versatile industrial lasers in the product lineup. Operating within the nanosecond pulse width range, these lasers are suitable for a wide range of industrial applications, offering users unparalleled flexibility. They are completely maintenance-free, allowing users to focus on results rather than time-consuming and costly maintenance plans.

• Processing flexibility: Utilizing a non-contact process, it can generate high-precision, high-speed permanent marks. Laser marking requires no consumables, is computer-generated, and adapts to diverse needs.

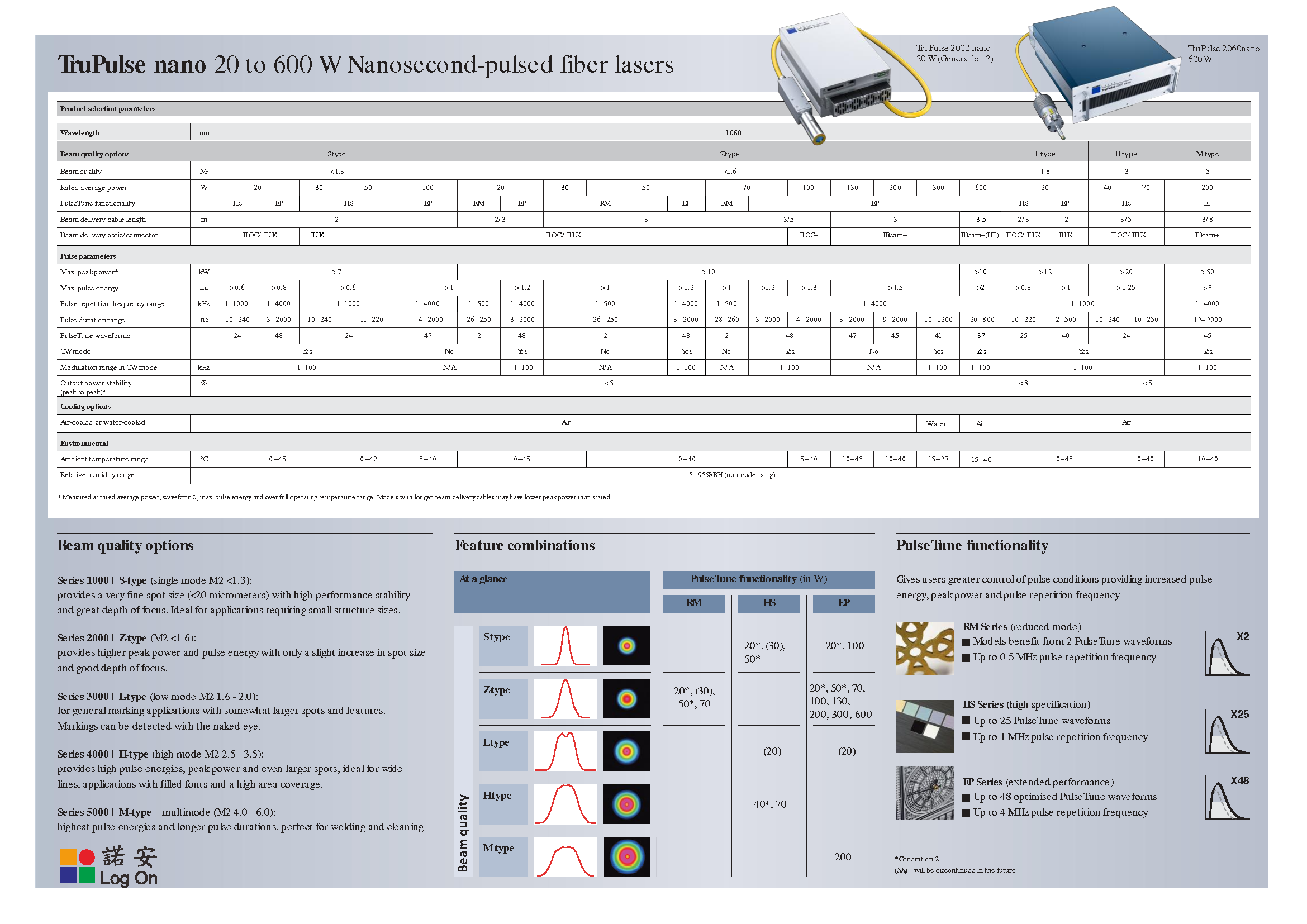

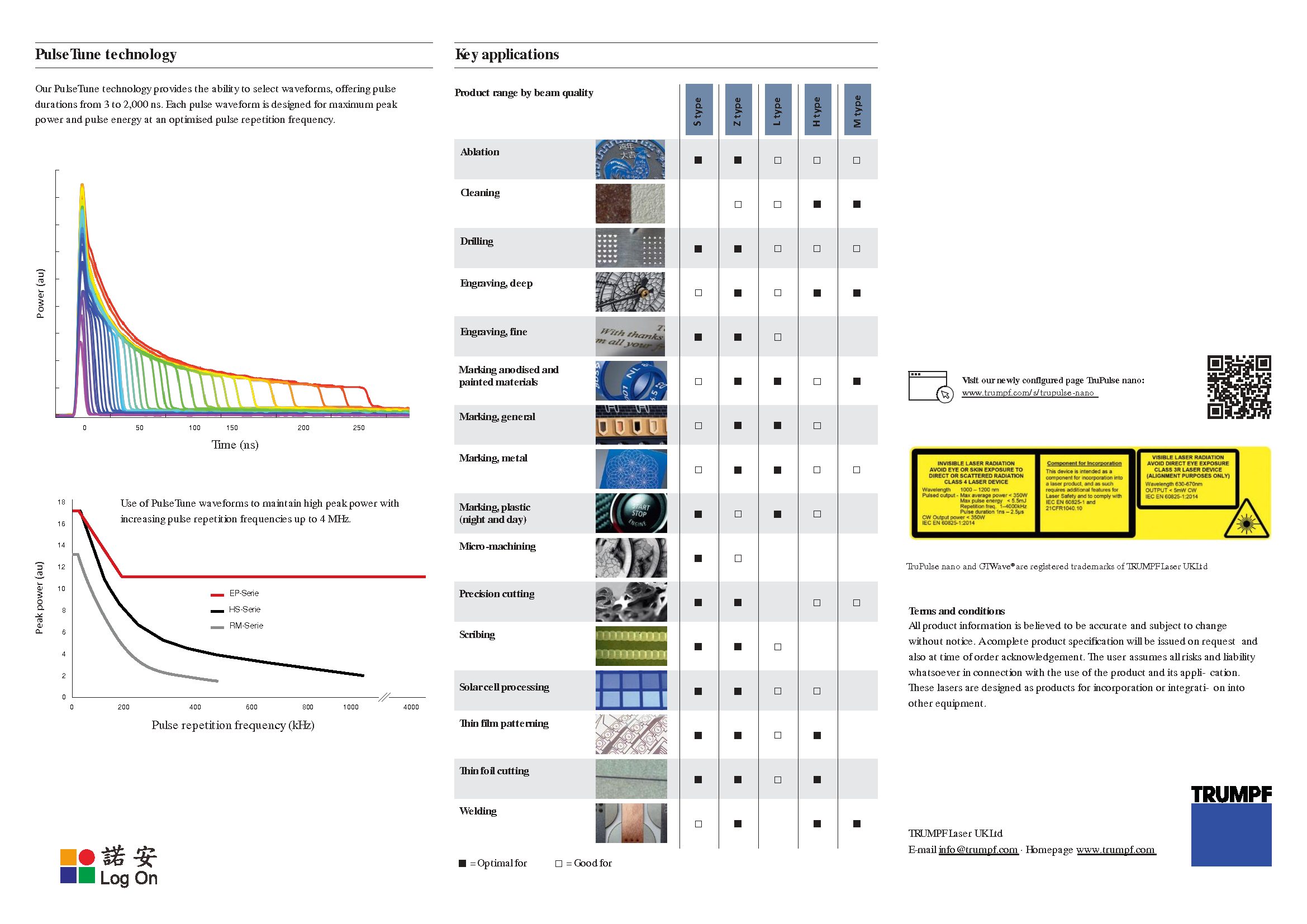

• Technological innovation: PulseTune technology expands micromachining capabilities, enabling OEM integrators to flexibly control pulse width and peak power, achieving high pulse frequencies while maintaining stable peak power.

• Application versatility: It offers up to 48 waveforms, which can optimize pulse characteristics for different applications, improving process quality and production efficiency.

• Operational convenience: The design of the pulsed fiber laser requires no maintenance throughout its entire lifecycle, eliminating maintenance costs and allowing focus on production results.

• Nanosecond welding: Suitable for welding various products, unrestricted by materials, and capable of joining thin metal components (including highly reflective and conductive metals).

• Laser cutting: The laser beam is easily programmable, enabling precise cutting of various thicknesses and materials (including reflective metals, ordinary metals, gemstones, ceramics, etc.). Users can control beam intensity, width, and heat, allowing for high-precision cutting of complex shapes.

• Laser etching of coatings: It can precisely strip metal or industrial compound coatings from electronic products such as semiconductors and microprocessors.

• Laser cleaning: Removes surface residues and dirty coatings without damaging the base material.

• Layer-by-layer part manufacturing based on 3D models, as well as high-precision laser drilling (using pulses to evaporate and melt materials to form holes, with precision controlled by monitoring the laser beam).

• Laser marking and engraving: Applied to various materials such as ceramics, synthetic materials, and metals.