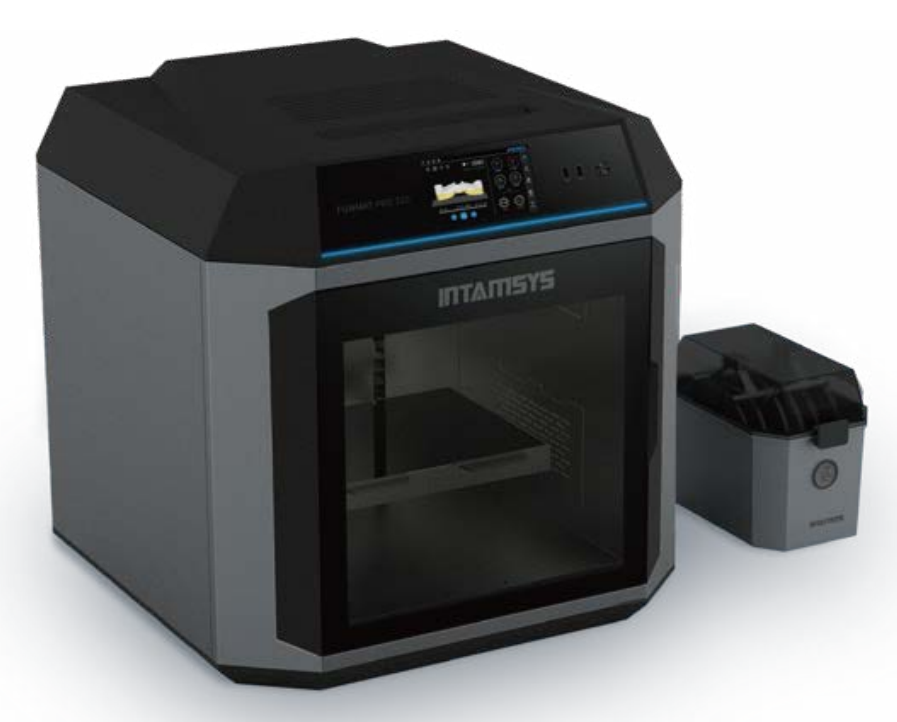

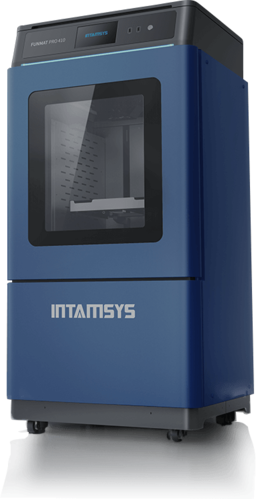

Brand:INTAMSYS

Model :

FUNMAT PRO 310

INTAMSYS FUNMAT PRO 310 constant-temperature chamber design and full-size printing capability (305×260×260mm), the FUNMAT PRO 310 fully meets the needs of engineers across various industries. The plug-and-play, easily detachable modular IDEX (Independent Dual Extruder) design enables multiple printing modes. It delivers excellent printing stability, while the high-temperature chamber (up to 100°C) ensures printed parts have good mechanical strength and no warping or cracking. The printer is compatible with a wide range of engineering plastics, including ABS, PC, PC-ABS, PA, PA-CF, and ASA.

| Technical Parameters | Details | Technical Parameters | Details |

|---|---|---|---|

| Technology Principle | FFF (Fused Filament Fabrication) | Chamber Temperature | Max. 100°C |

| Printing Size |

Single - extruder: 305 x 260 x 260 mm; Dual - extruder: 260 x 260 x 260 mm |

Platform Temperature | Max. 160°C |

| Layer Thickness | 0.1 - 0.3 mm | Leveling Method | Adaptive multi - point leveling (up to 100 points) |

| Number of Extruders | 2 (Independent) | Filament Diameter | 1.75 mm |

| Extruder Temperature | Max. 300°C | Recommended Printing Materials* |

PA6/66, PA6 - CF, PA12 - CF, PC, PC - ABS, ABS, ASA, PLA, HIPS, PVA |

| Printing Speed | Max. 120 mm/s | Intelligent Design |

Filament shortage alarm, remote monitoring, remote control, remote printing |

| Nozzle Diameter | Standard: 0.4 mm (Optional: 0.25, 0.6 mm) | Material Hopper Design |

Independent hoppers, integral sealed and dry design; Reusable molecular sieves ensure low humidity; Equipped with sensors to monitor the internal environment of hoppers in real - time |

| Power Supply |

100 - 132V/15A or 200 - 240V/7A, 50/60 Hz |

Spool Quantity | 2 (Max 1Kg/pcs) |

| Maximum Power | 1600W | Movement Speed | Max.XY 500 mm/s |

| Data Connection | WiFi, Ethernet, USB | Resolution | XY: 16μm; Z: 1.25μm |

| Operation Screen | 7 - inch smart touch screen | Air Filtration | HEPA filter + Activated carbon |

| Printing Platform | PI plate heating + spring steel magnetic suction printing bed | Overall Dimensions | 700655700 mm |

| Cooling System | Active air cooling | ||

| Extruder Maintenance | Quick - release design, easy to install and disassemble, convenient for maintenance |